Tackling Rising Labor and Energy Costs with Smart Automation Showcased at K 2025

Under the guiding motto “Your Partner for Presses and Automation”, WICKERT will present itself at this year’s K 2025, taking place from October 8–15 in Düsseldorf, as a full-service provider of tailor-made automation solutions for hydraulic presses. Visitors will find the company at booth 14A41 in Hall 14, where WICKERT will showcase not only its long-standing expertise in press technology but also its innovative strength in automation and system integration.

As one of the leading specialists in custom-engineered press systems, WICKERT offers solutions that cover a wide variety of applications. Its portfolio extends across the processing of composites, rubber, friction materials, plastics, and powder—including production environments that require cleanroom conditions. By combining deep engineering knowledge with forward-looking automation concepts, WICKERT has established itself as a reliable partner for manufacturers in demanding industries such as automotive, aerospace, energy, and medical technology.

Fully Automatic Spraying System for Rubber and Plastics Processing

Fully Automatic Spraying System for Rubber and Plastics Processing

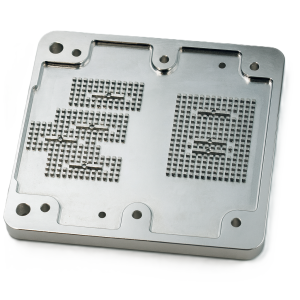

One of the highlights at K 2025 will be WICKERT’s newly developed fully automatic spraying system, designed specifically for rubber and plastics processing in hydraulic presses. Traditionally, the application of release and flow agents has been carried out manually—an approach that is not only time-consuming but also prone to human error. Manual spraying often results in inconsistent coating, which can negatively impact both product quality and process reliability, while also creating workplace safety risks due to operator exposure to aerosols.

The automated spraying innovation from WICKERT solves these challenges. The system operates with movable distribution beams, which are fitted with individually adjustable nozzles. A dedicated spraying unit moves back and forth between the upper and lower die, applying release and flow agents homogeneously and reproducibly. This guarantees consistent coating, stable part quality, and improved occupational safety.

Another advantage of the system is its retrofit capability. It can be easily integrated into existing hydraulic presses without major structural modifications, enabling manufacturers to upgrade their production processes efficiently and cost-effectively. By replacing manual spraying with automation, companies not only gain higher reproducibility and throughput but also contribute to safer working environments.

Automation as a Strategic Reaction to Industry Requirements

Due to the persistent lack of qualified personnel and the increasing expenditure on high-qualified staff, the urge to automate manufacturing processes is higher than ever. Especially, hydraulic press technology manufacturers find themselves under mounting demands for enhanced productivity, flexible system design, and sustainable cost reduction.

WICKERT meets these challenges in the industry with a wide spectrum of automation services. Its service reaches from component creation and concept confirmation right through to feasibility studies, system planning, and project management in total. With its status as a general contractor, it is possible for the company to provide entire production lines on a turnkey basis, with perfect integration of presses, handling systems, and peripherals.

Depending on customer requirements, WICKERT develops tailor-made automation concepts that range from partially manual solutions to fully automated production lines. This flexible approach allows manufacturers to select the degree of automation that best fits their current and future needs, whether for small-scale systems or large-capacity presses.

From Smart Automation to the Smart Factory

From Smart Automation to the Smart Factory

WICKERT’s innovation strategy is closely aligned with the vision of the Smart Factory. Upon request, its presses can be fully equipped with sensors and actuators, enabling comprehensive data collection during production. The range of data includes information on machine wear and performance for predictive maintenance, as well as detailed metrics on production output, process stability, and product quality.

By leveraging such operational and process data, manufacturers can optimize their production in real time and extend equipment lifespan. Moreover, WICKERT presses can be integrated into higher-level process control platforms and networked with other machines and systems. This creates a digitally connected production environment that supports Industry 4.0 initiatives and ensures customers remain competitive in global markets.

From Machine Manufacturer to System Integrator

Over the past decade, WICKERT has undergone a significant transformation—from a pure manufacturer of hydraulic presses into a holistic system integrator and automation partner. This strategic evolution reflects the increasing demand for complete solutions rather than stand-alone machines.

In fact, within the last five years, the share of press systems sold with automation has grown from 20% to 60% of WICKERT’s total sales. This demonstrates the clear market trend towards integrated automation solutions and highlights the company’s successful positioning in this area.

Beyond automation, WICKERT also places strong emphasis on intelligent machine design. By incorporating energy-efficient drive concepts, optimized hydraulic systems, and ergonomically designed operator interfaces, the company helps its customers reduce operating costs, lower energy consumption, and improve workplace efficiency.

Conclusion

With its presence at K 2025 in Düsseldorf, WICKERT underscores its role as a forward-looking partner for companies seeking to enhance their competitiveness through press technology and automation. The company’s offering—ranging from individual presses to fully networked production lines—demonstrates how customized automation, digitalization, and intelligent machine design can provide real answers to today’s manufacturing challenges.

At booth 14A41 in Hall 14, trade visitors will have the opportunity to experience firsthand how WICKERT combines technical expertise, innovation, and customer orientation to deliver future-proof solutions for a wide spectrum of applications.

https://www.wickert-presstech.de/en/

#wickert #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #ModernPlasticskorea

In response to the increasing demand for PFAS-free materials, Asahi Kasei is developing a PFAS-free low-friction LEONA polyamide and will introduce the new grade for the first time in

In response to the increasing demand for PFAS-free materials, Asahi Kasei is developing a PFAS-free low-friction LEONA polyamide and will introduce the new grade for the first time in  Conventional approaches to

Conventional approaches to

Fully Automatic Spraying System for Rubber and Plastics Processing

Fully Automatic Spraying System for Rubber and Plastics Processing From Smart Automation to the Smart Factory

From Smart Automation to the Smart Factory

Under the new regulation, modified and stricter assessment criteria are applied: The permissible limits after decontamination for

Under the new regulation, modified and stricter assessment criteria are applied: The permissible limits after decontamination for